Air film cooling is an important cooling method for gas turbine blades, but due to the multi-scale effect of gas film cooling, it is difficult to accurately calculate the cooling efficiency of gas film cooling by using the source term model of simplified geometry or the RANS turbulence model considering the real geometry.

1. Calculation configuration and numerical simulation method

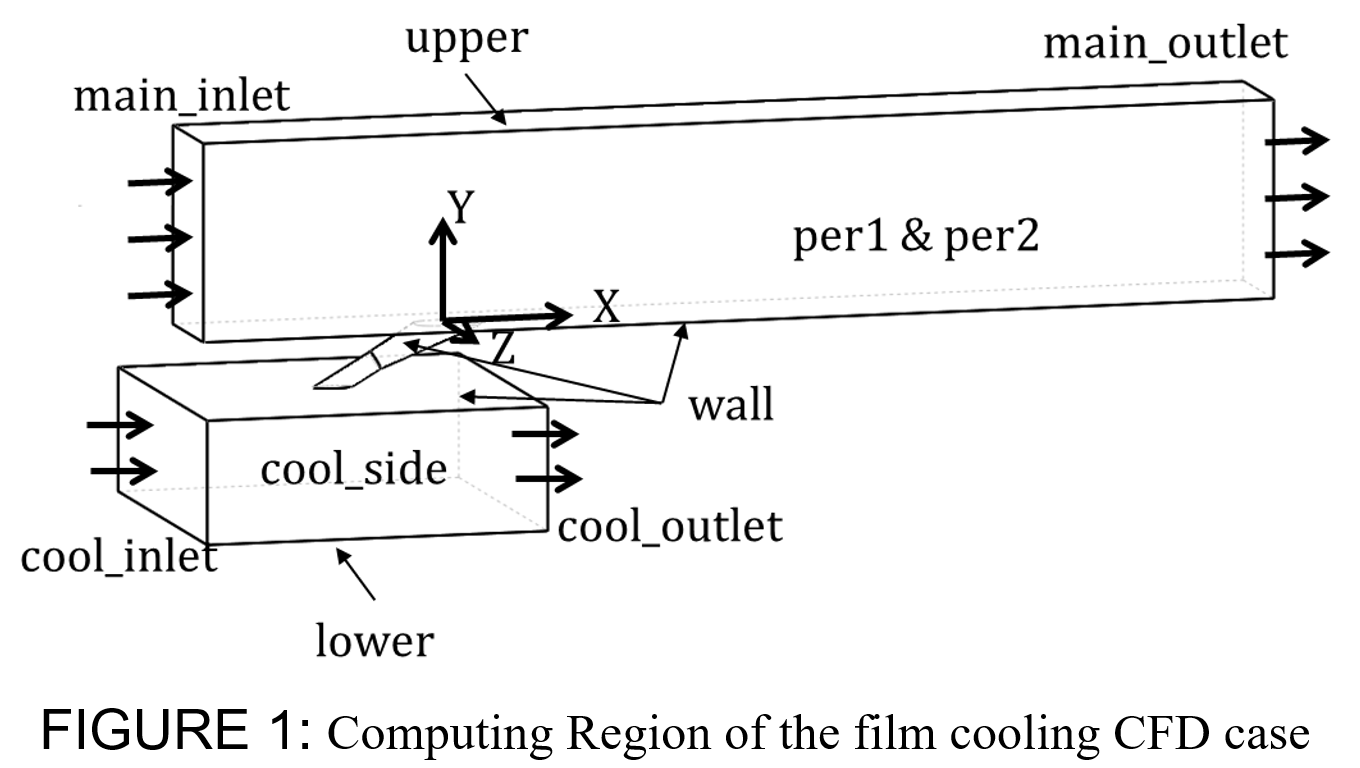

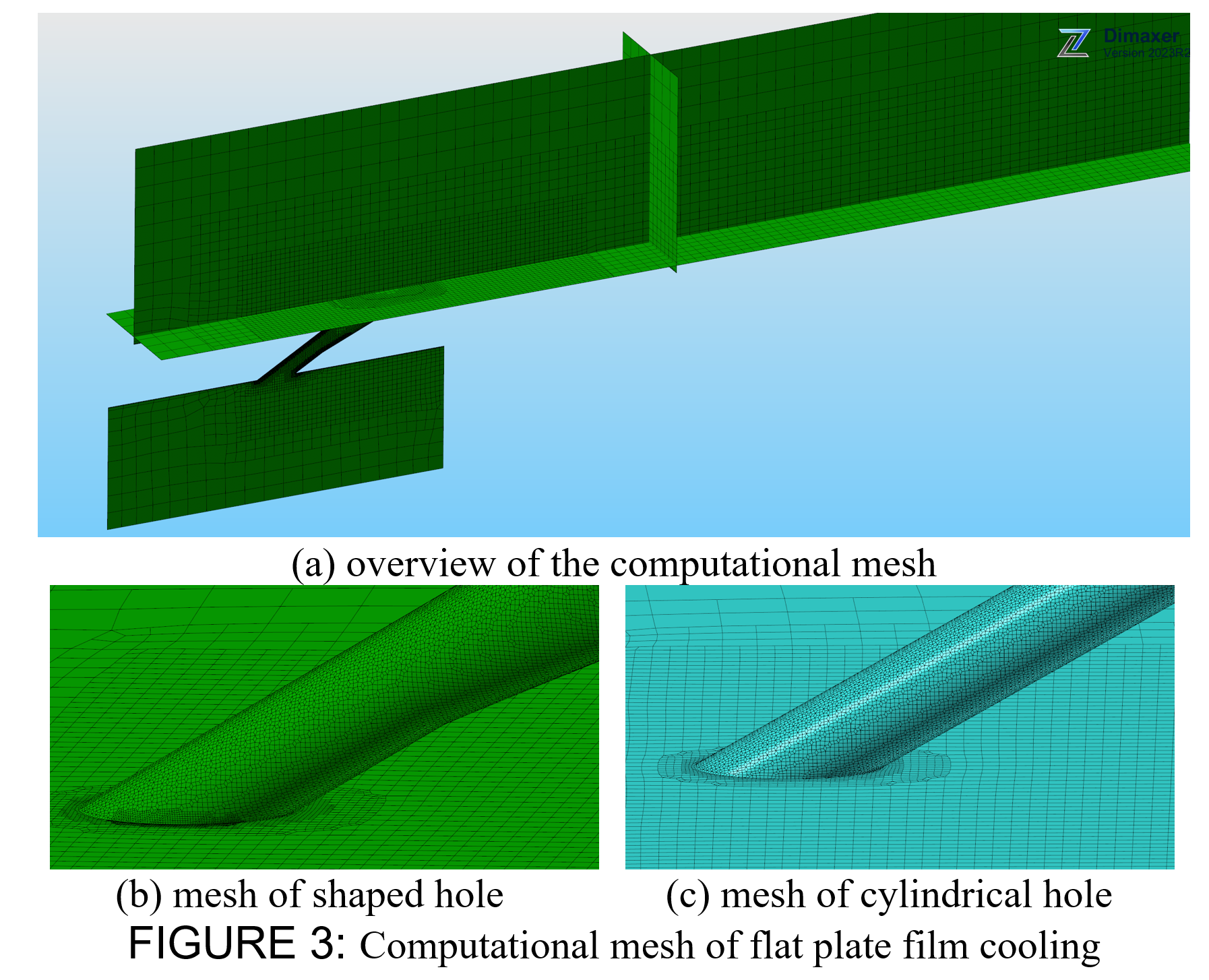

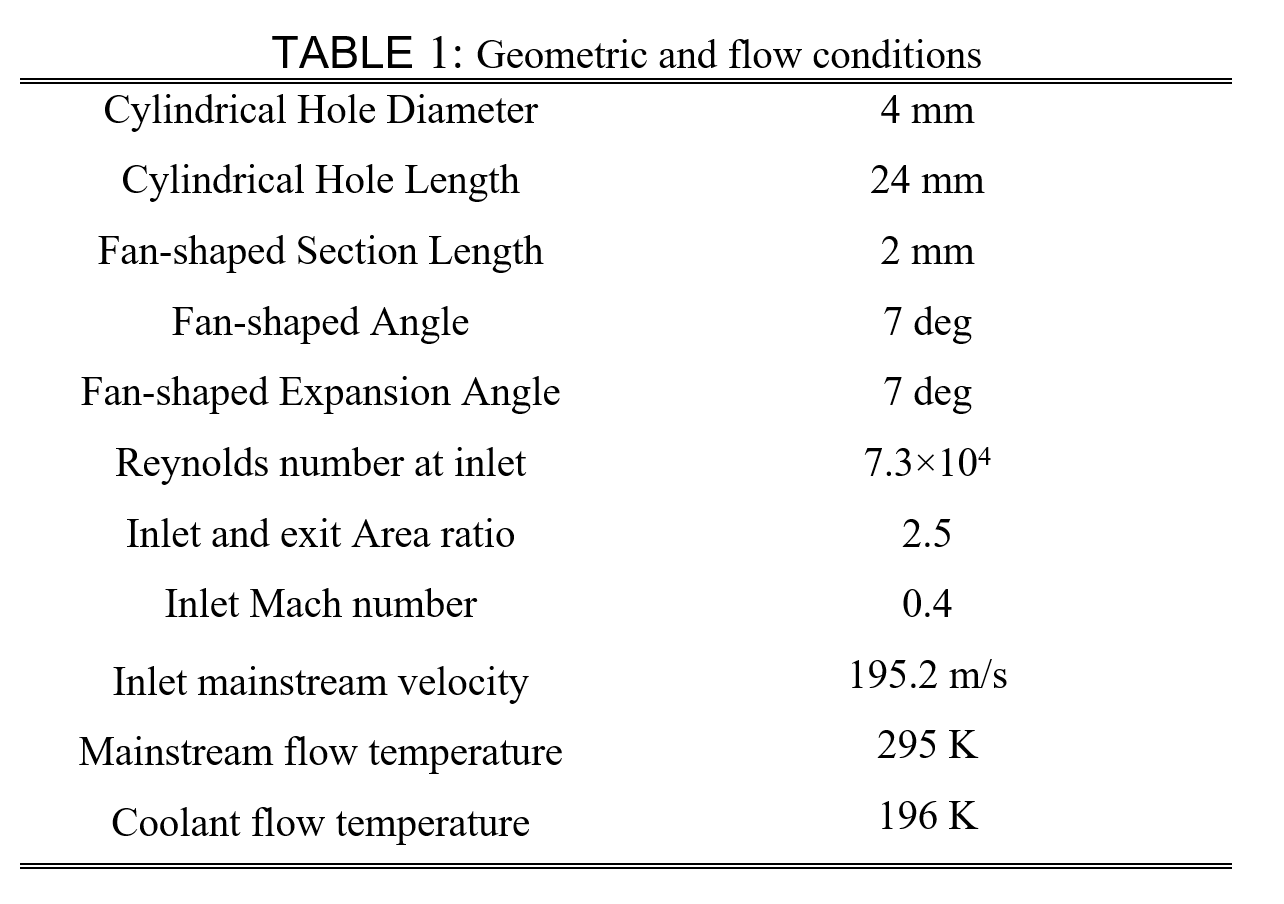

Based on the periodic characteristics of air film cooling in the circumferential direction, a single air film cooling hole was selected as the research object. As shown in Figure 1, the computational domain used for the flat plate film cooling study is divided into two rectangular regions, the main stream zone and the cold air zone. The two rectangular areas are connected by an air film hole.

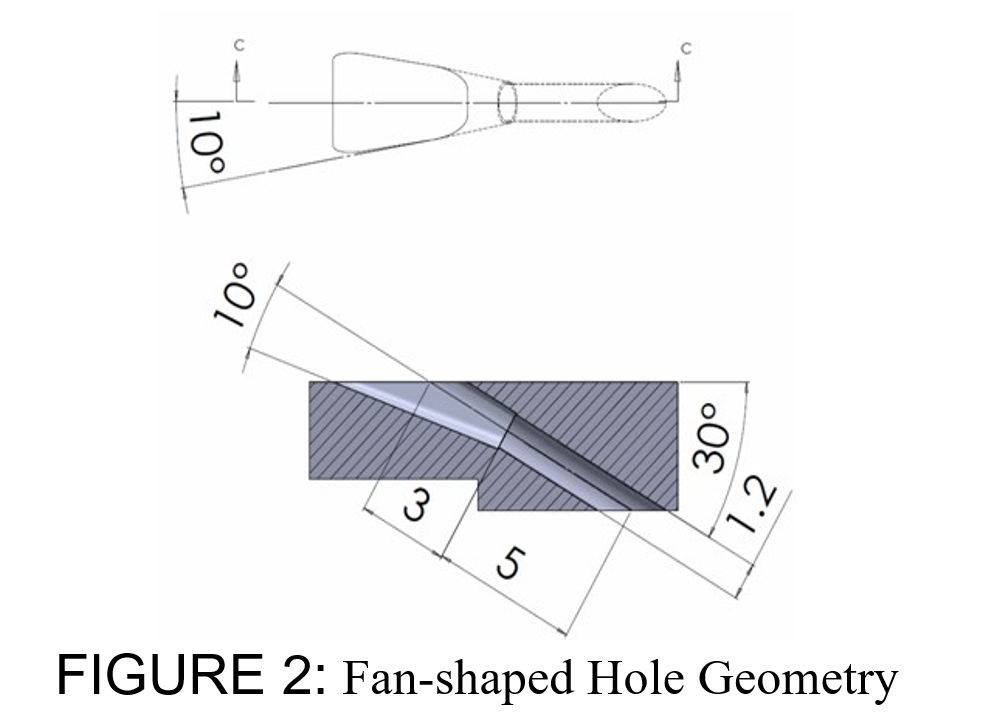

The geometry of the sector hole is shown in Figure 2: the origin is located on the centerline of the air film cooling hole. The coordinates x, y, and z correspond to the flow direction, wall normal, and circumference, respectively. The distance between the entrance of the main stream and the center of the air film hole is 15D, the length of the main stream is 60D, the height of the main stream is 9D, and the spacing distance is 6D.

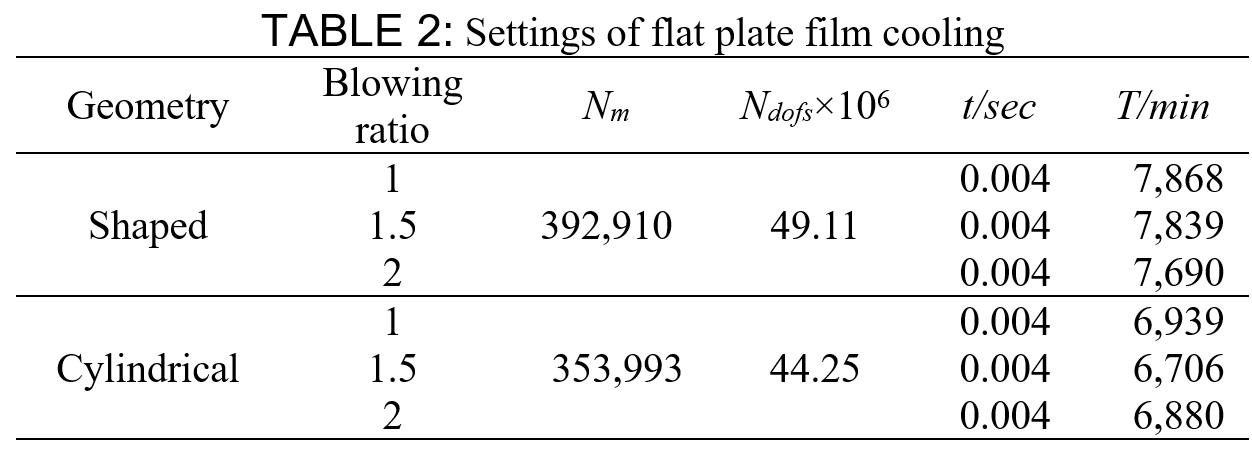

Table 2 shows the calculation setup and the total GPU time used: Dimaxer was used to solve with 4th order precision on 4 GPUs, and the calculation reached statistical steady state within a few days.

2. Analysis of calculation results

2.1 Average results

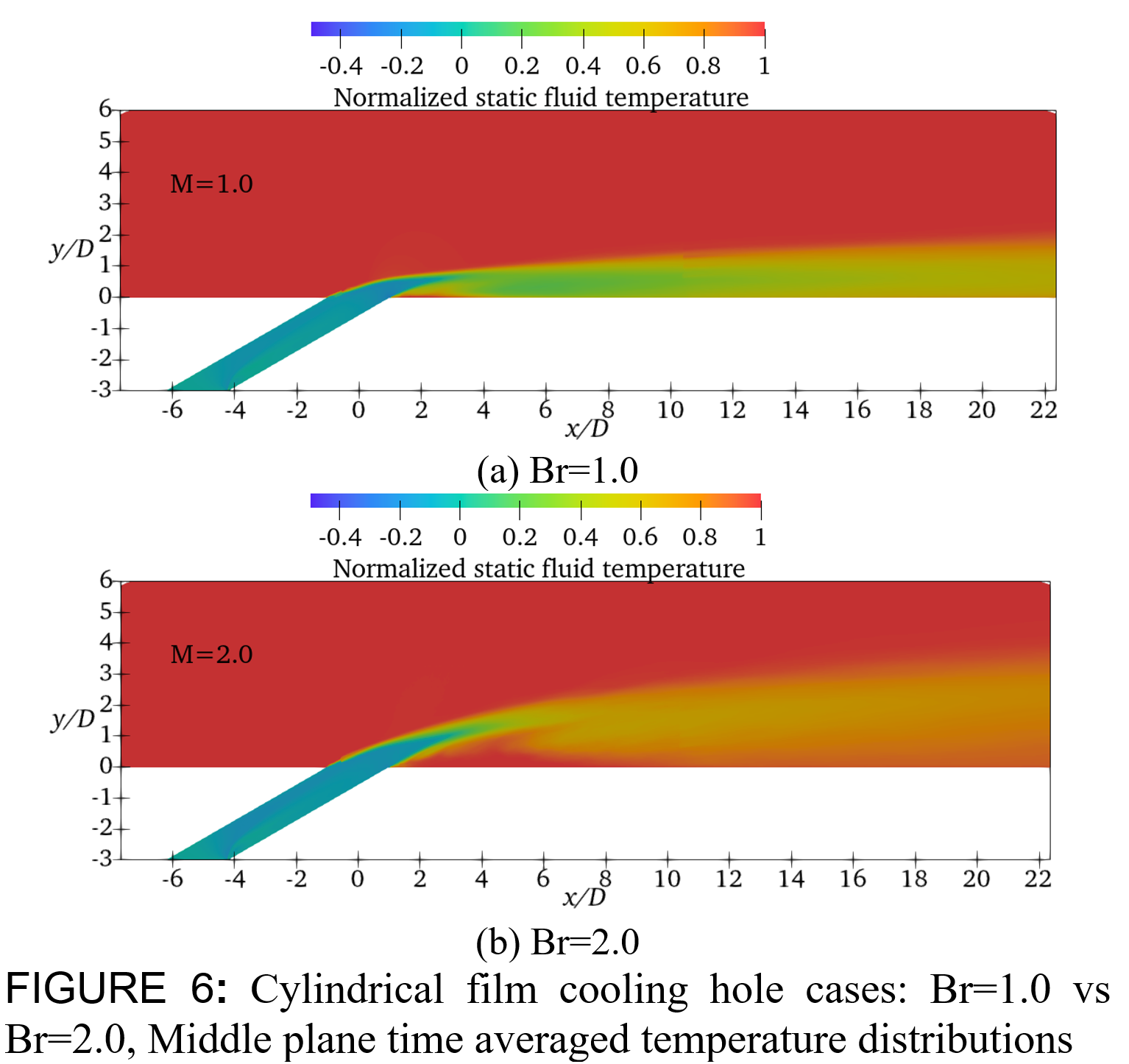

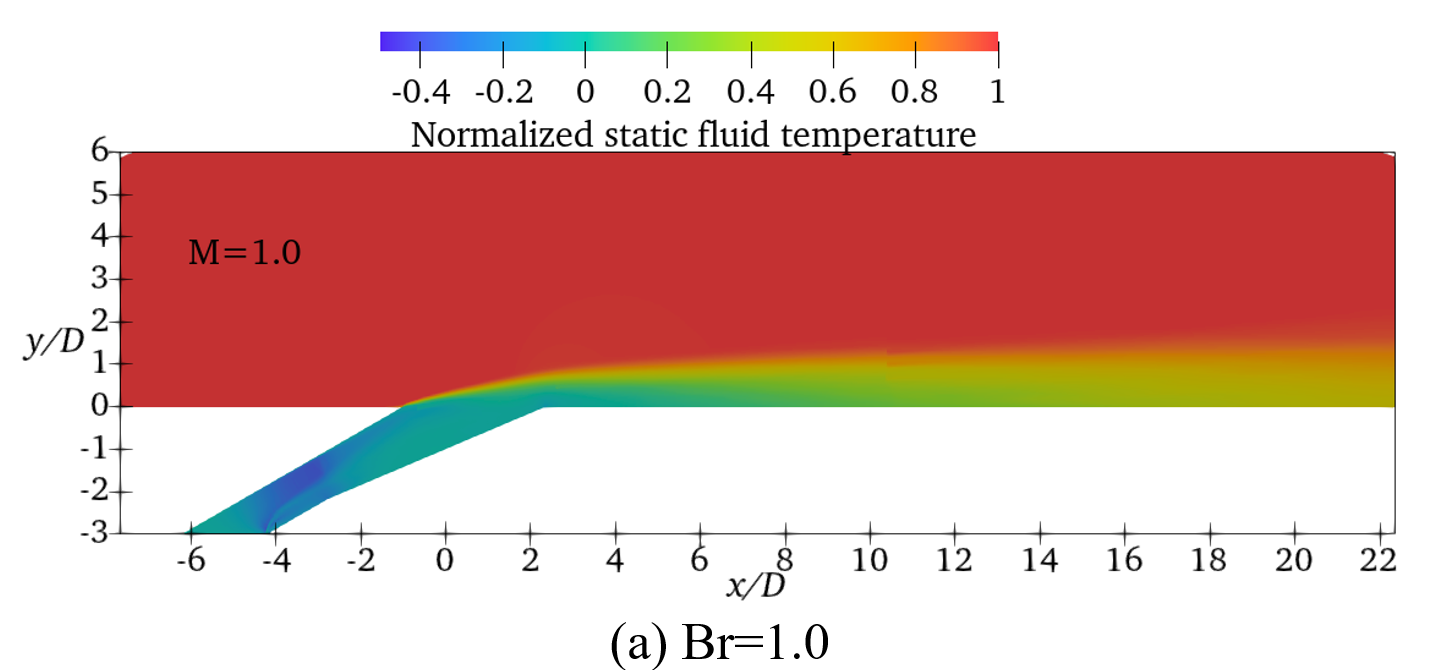

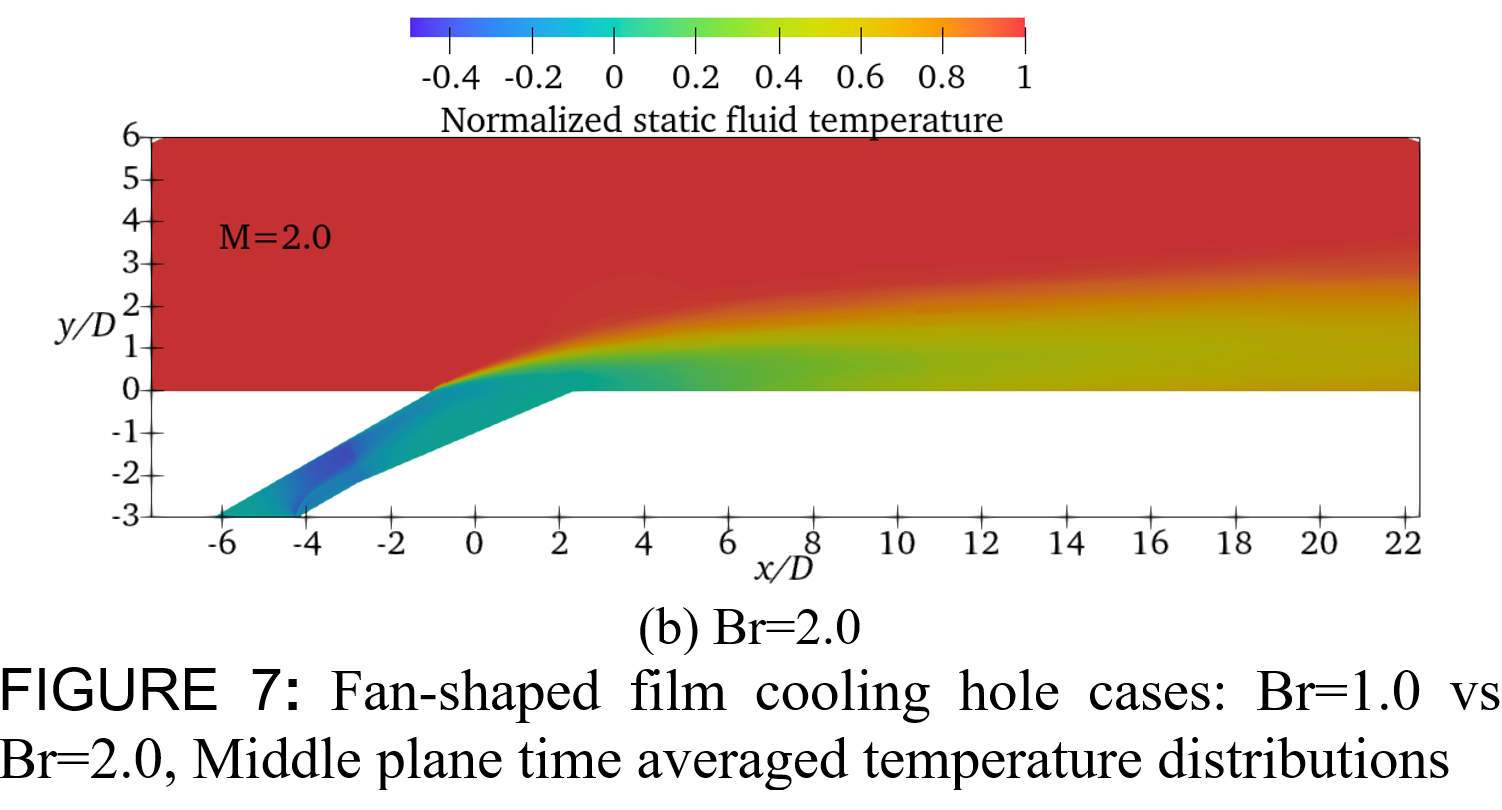

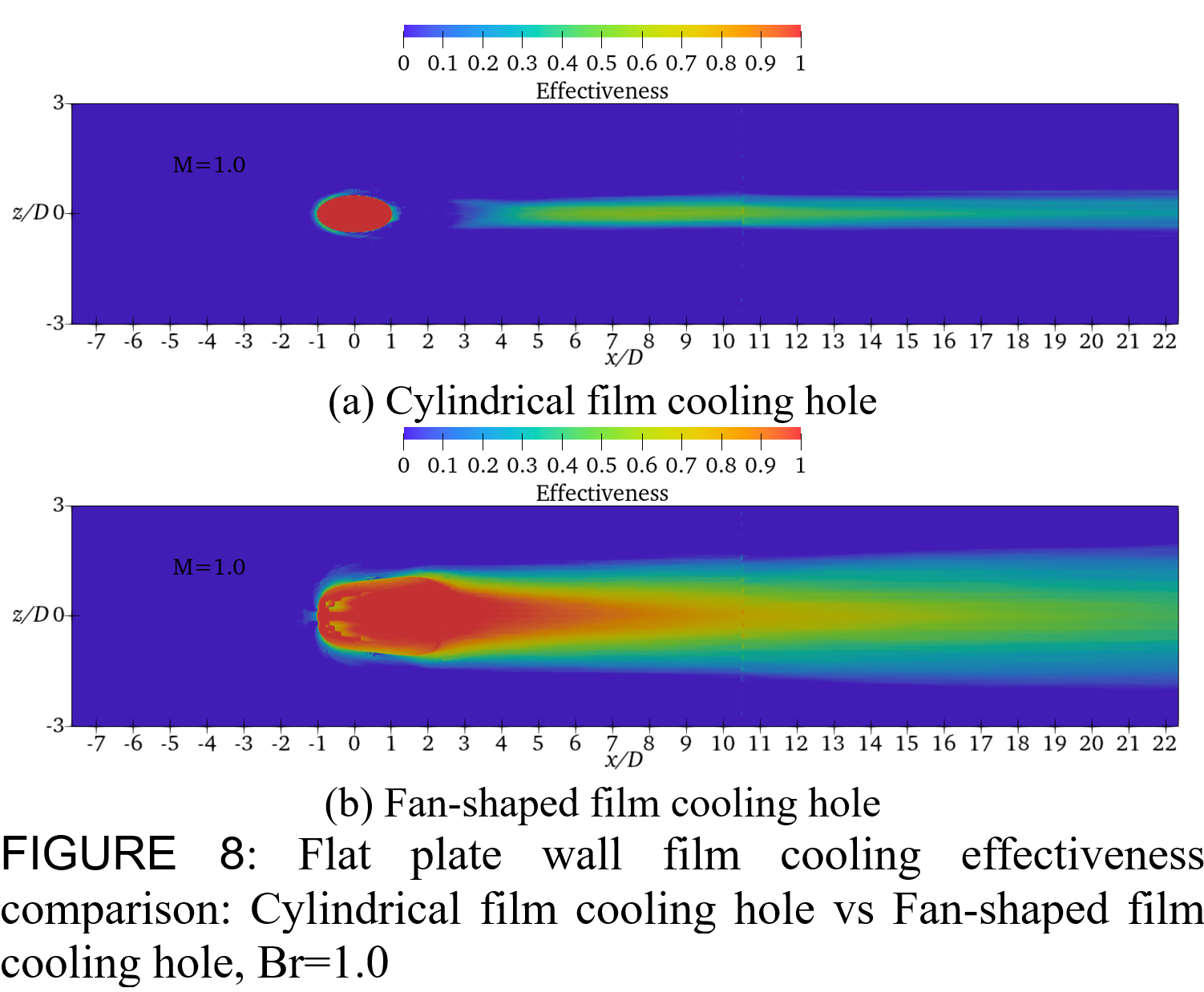

The time-averaged flow field of different air film holes, as shown in Figures 6, 7 and 8: It can be seen from the figure that the cold air jet of the fan-shaped hole is more evenly distributed on the plate, and a better cooling effect is obtained.

2.2 Transient Results

2.2.1 Flow direction section

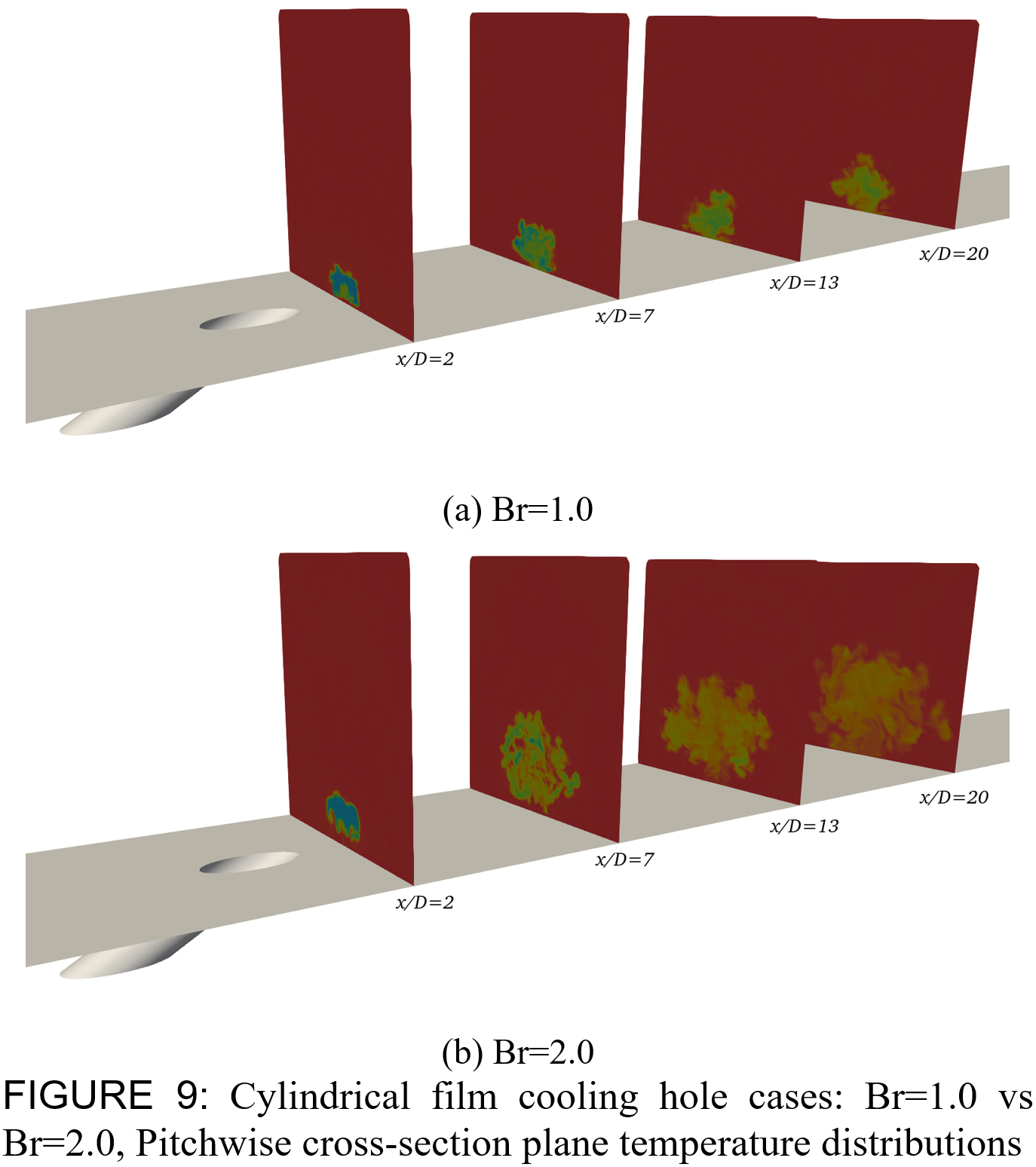

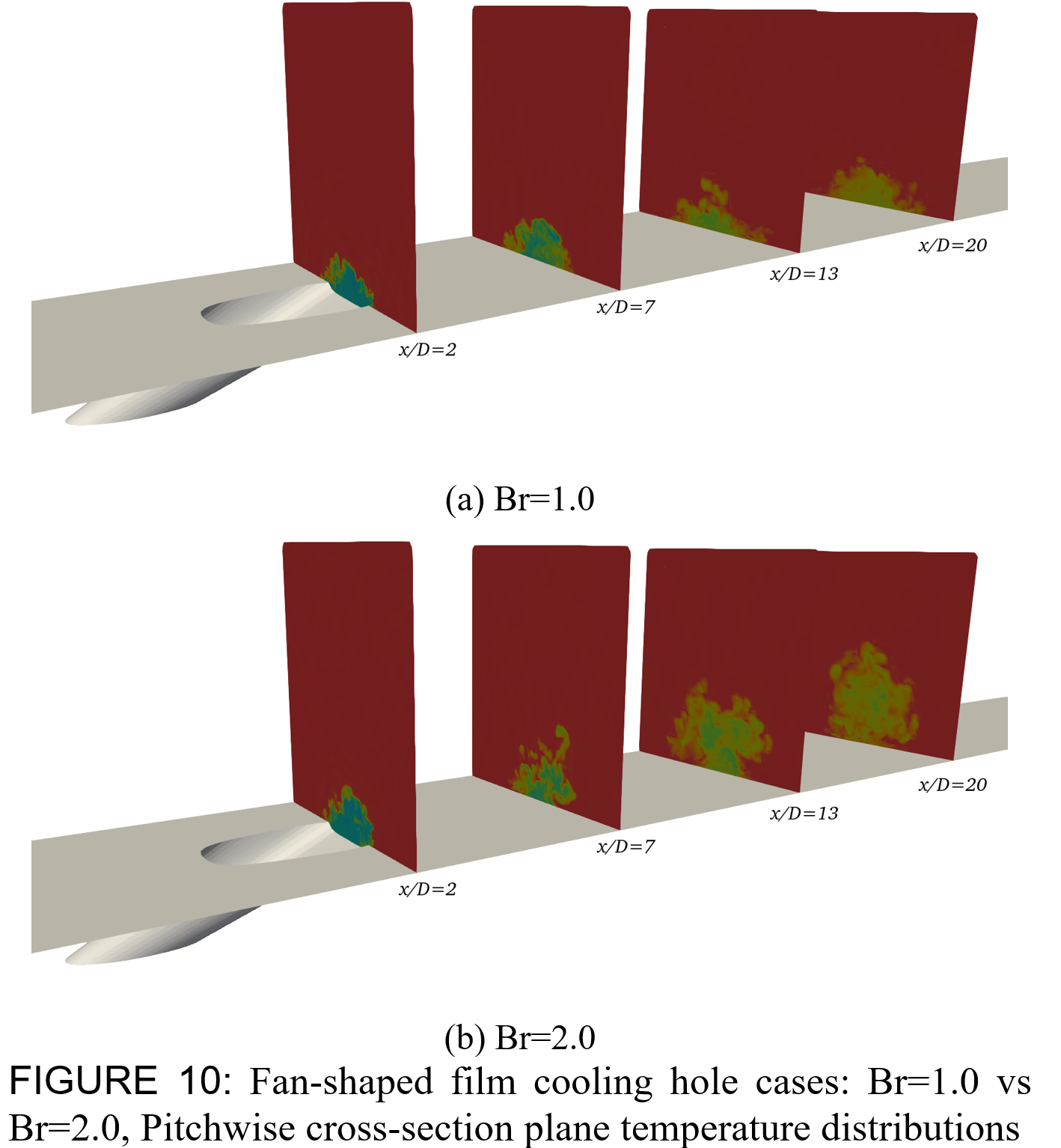

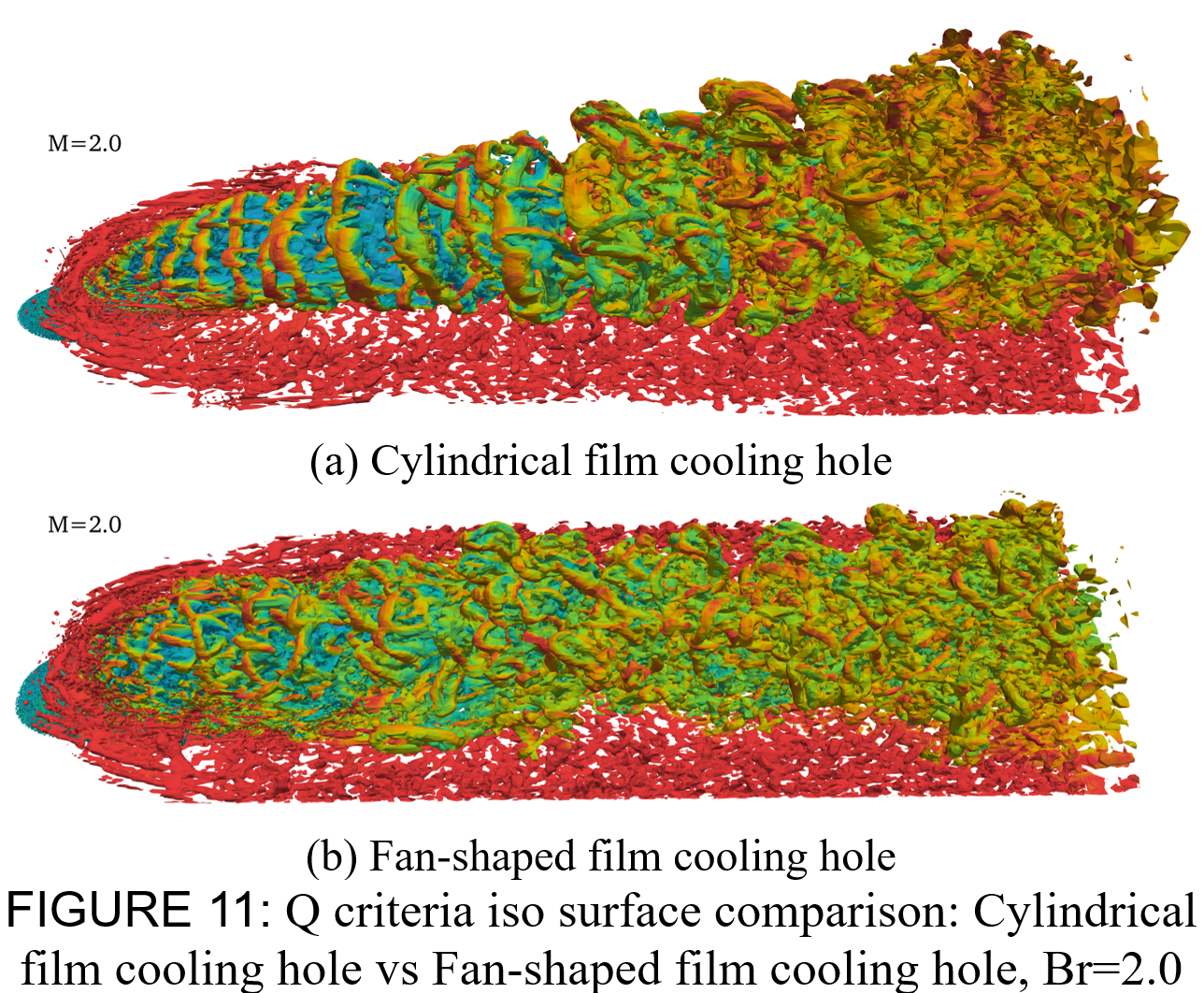

As shown in Figs. 9, 10 and 11, the high velocity of the round-hole cold air jet forms a stronger kidney-shaped vortex, which reduces the lateral diffusion of the air flow, and the coverage effect on the wall surface is poor, and the cooling efficiency is reduced.

Image

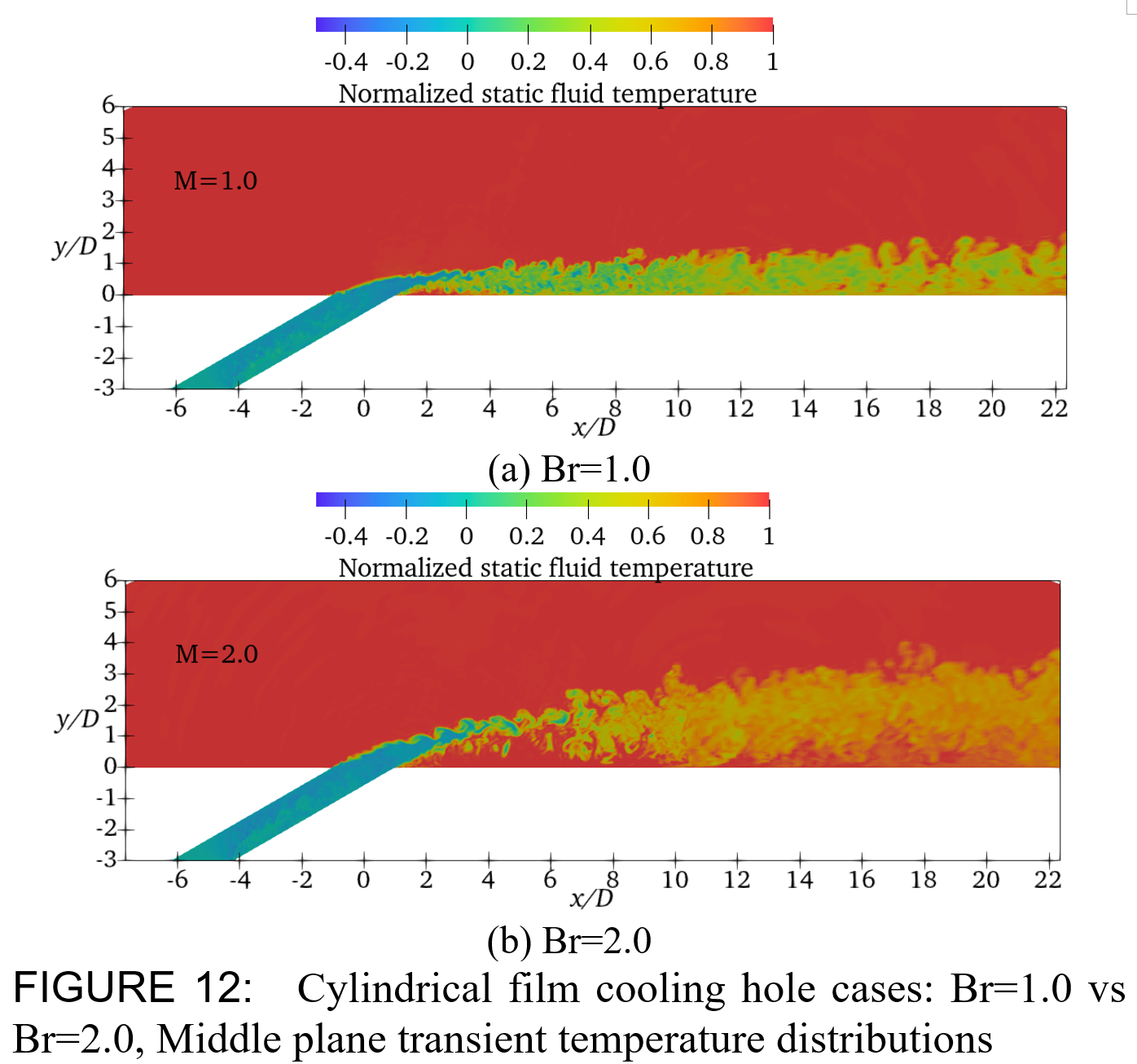

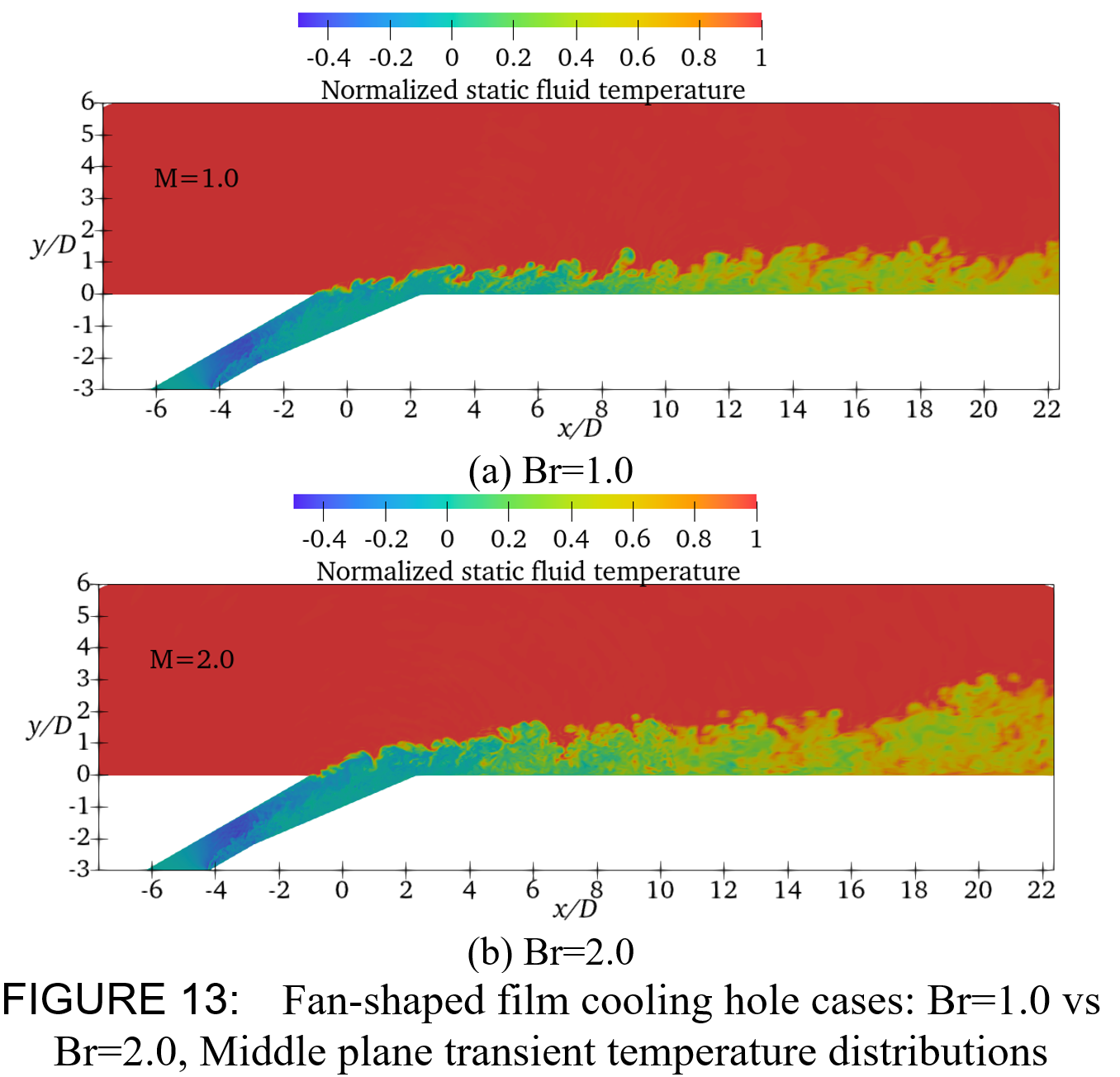

2.2.2 Medium section

3. Conclusion

In this paper, Dimaxer is used to carry out a fourth-order precision large eddy simulation study on round holes and sector holes, and rich flow field information is obtained, and the analysis of the flow field shows that compared with round holes, the sector holes make the cooling air flow spread rapidly after injection, forming a larger sector area, increasing the contact area between the cooling air flow and the wall, and improving the cooling efficiency.

Rankyee ń▓żICPÕżć2023060583ÕÅĘ